SA-Tools' Thread End Mills Cutting Up to 55HRC

2023-10-23Mould & Die

In the world of precision machining, achieving the perfect balance between hardness and machinability is crucial. At SA-Tools, we have harnessed cutting-edge technology and expertise to manufacture thread end mills that can handle materials with hardness levels up to 55HRC (Rockwell C scale). In this article, we explore the significance of this capability, the challenges it presents, and how SA-Tools has pioneered the way in machining high-hardness materials.

Understanding Material Hardness

Material hardness refers to the resistance of a material to plastic deformation, indentation, or penetration. The Rockwell C hardness scale, denoted as HRC, measures the hardness of metallic materials, particularly those with high hardness levels. Materials with a 55HRC rating are considered to be very hard and pose a significant challenge to conventional machining processes.

Challenges in Machining High-Hardness Materials

Machining materials with high hardness levels, such as those up to 55HRC, presents several challenges to manufacturers. Some of the key obstacles include:

- Tool Wear: High-hardness materials have abrasive properties that cause excessive tool wear, leading to shorter tool life and reduced machining efficiency.

- Heat Generation: The cutting process generates heat, and in the case of hard materials, this heat can rapidly accumulate, causing thermal damage to the cutting tool and workpiece.

- Surface Integrity: Machining high-hardness materials can result in surface defects, residual stresses, and microstructural changes, impacting the component's integrity and performance.

- Chip Control: Proper chip evacuation becomes critical when machining hard materials. Inadequate chip control can lead to chip recutting, which exacerbates tool wear and surface quality issues.

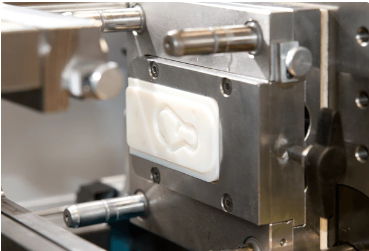

SA-Tools' Innovation in Machining High-Hardness Materials

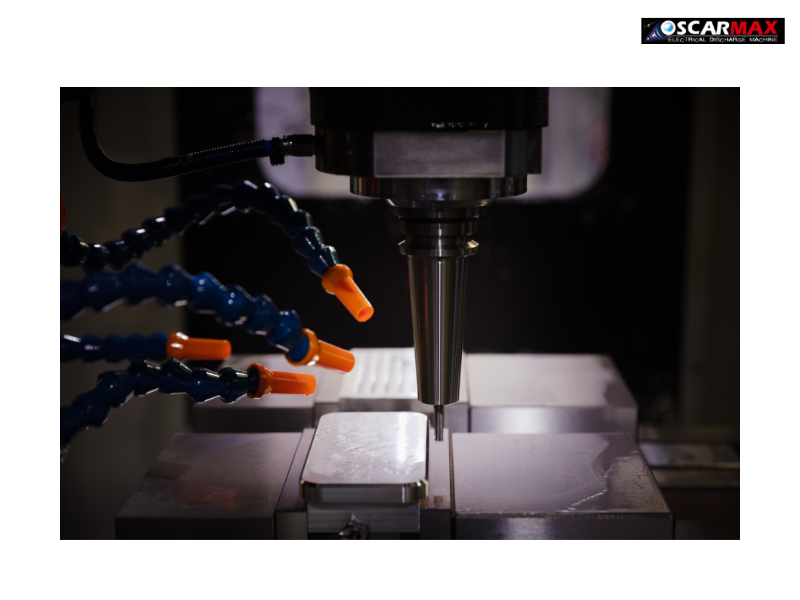

SA-Tools has risen to the challenge of machining materials with hardness up to 55HRC, pioneering cutting-edge solutions to overcome the obstacles that come with high-hardness machining. Our innovative approaches include:

- Advanced Tool Materials: We employ high-quality and specially formulated tool materials, such as tungsten carbide, cermet, and ceramic, which exhibit exceptional hardness and wear resistance.

- State-of-the-Art Coatings: SA-Tools utilizes advanced coatings, such as titanium nitride (TiN), titanium carbonitride (TiCN), and diamond-like carbon (DLC), to enhance tool durability, reduce friction, and manage heat generation during machining.

- Precision Tool Geometry: Our thread end mills feature meticulously designed cutting geometries tailored for high-hardness materials, optimizing chip formation and reducing cutting forces.

- Coolant Strategies: SA-Tools implements effective coolant strategies, including through-tool coolant delivery, to mitigate heat buildup during machining, ensuring consistent tool performance.

Advantages of SA-Tools' Thread End Mills for High-Hardness Materials

- Extended Tool Life: SA-Tools' thread end mills are engineered to withstand the abrasive nature of high-hardness materials, resulting in prolonged tool life and reduced tool replacement costs.

- Enhanced Surface Finish: The precision and advanced coatings of our thread end mills result in improved surface integrity, minimizing surface defects and residual stresses.

- Increased Productivity: By efficiently machining materials up to 55HRC, SA-Tools enables manufacturers to streamline their processes and boost overall productivity.

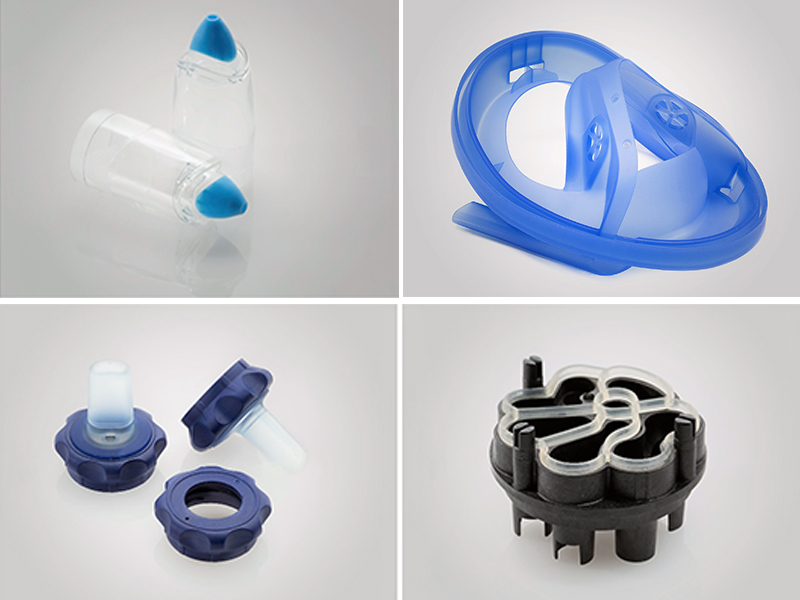

- Versatility: SA-Tools' thread end mills can handle a wide range of materials, from soft to extremely hard, offering versatility for diverse machining applications.

Conclusion

As a trailblazer in the precision machining industry, SA-Tools has demonstrated its commitment to innovation and excellence by developing thread end mills capable of cutting materials up to 55HRC. Our dedication to overcoming the challenges of high-hardness machining has resulted in tools that provide extended tool life, superior surface finish, and increased productivity for our valued customers.

As we continue to push the boundaries of machining technology, SA-Tools remains focused on delivering cutting-edge solutions that empower manufacturers to achieve exceptional results in their high-hardness machining endeavors. With our thread end mills leading the way, we look forward to a future of unparalleled precision and efficiency in the world of machining high-hardness materials.

Contact us to find your perfect thread end mill.