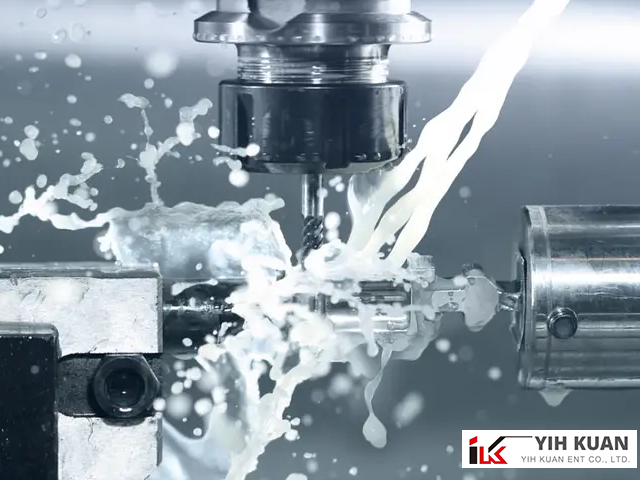

Grinding Stone: The Backbone of Precision Manufacturing

2024-03-22Machinery From:Sea Shore Diamond

Grinding stones, essential tools in the manufacturing and industrial processing world, stand at the forefront of precision, efficiency, and innovation. These tools, crafted from durable materials like diamond or cubic boron nitride, are pivotal in shaping, honing, and finishing metal, glass, and even concrete surfaces. Their unparalleled hardness and thermal conductivity make them ideal for cutting-edge applications across various sectors, including aerospace, automotive, and electronics.

Characteristics and Versatility

- Abrasive Quality and Material Composition: The effectiveness and durability of grinding stones largely depend on their composition. Superior abrasive materials ensure efficiency in cutting tasks and contribute significantly to the tool's longevity by maintaining its form and sharpness.

- Hard Materials Used: Employing diamonds and cubic boron nitride, renowned for their unparalleled hardness, grinding stones can withstand extensive wear. This resilience is crucial for applications involving tough materials, as it minimizes the need for frequent replacements.

- Precision and Minimal Wear: The exceptional hardness of these materials allows for precise operations on challenging surfaces without significant degradation of the tool, ensuring consistent performance over time.

- Variety of Shapes and Sizes: Customization options for grinding stones are vast, catering to specific industrial needs and machinery. This adaptability ensures that regardless of the task, there is an optimal grinding stone configuration available, enhancing the tool's utility across a wide range of applications.

Grinding Techniques and Technologies

The advancement of grinding techniques and the development of new technologies have significantly enhanced the capabilities of grinding stones, making them more efficient and versatile than ever before. Innovations in precision engineering and automation have led to the creation of grinding tools and machines that can achieve unparalleled levels of accuracy and finish. The introduction of computer numerical control (CNC) technology allows for the precise control of the grinding process, ensuring consistent results across a wide range of applications. Additionally, developments in electrochemical grinding (ECG) and ultrasonic-assisted grinding (UAG) offer solutions for working with hard-to-machine materials, reducing the physical stress on the grinding stone and extending its lifespan. These advancements not only improve the performance of grinding stones but also open up new possibilities for their application in various industries.

Broad Spectrum of Applications

- Aerospace Industry: Used for precision machining of critical components, ensuring the safety and reliability of aerospace vehicles.

- Automotive Industry: Essential for fine finishing of engine parts, improving their performance and extending their lifespan.

- Electronics Industry: Plays a key role in semiconductor production, where precision is critical for the functionality of electronic devices.

- Construction and Sculpting: Grinding stones are also used in construction for smoothing surfaces and in sculpting for detailed work on stone and metal.

- Jewelry Making: Critical for shaping and polishing precious stones and metals, contributing to the beauty and value of the finished pieces.

These points illustrate the essential role of grinding stones in various industries, highlighting their importance in achieving precision, efficiency, and the high-quality finish required in modern manufacturing and processing.

Sea Shore Diamond Industrial Co., Ltd. (SSDC): Pioneering Precision with Grinding Stones

As the narrative transitions from the fundamental aspects of grinding stones to the specialized capabilities of Sea Shore Diamond Industrial Co., Ltd. (SSDC), it becomes evident how SSDC's expertise and innovation in superabrasive manufacturing align with the demanding needs of precision manufacturing.

Tailoring Excellence in Superabrasives

SSDC stands as a beacon of innovation and quality in the production of grinding stones. By leveraging advanced materials and cutting-edge manufacturing techniques, SSDC crafts grinding stones that exceed industry standards for precision, durability, and performance. Their commitment to research and development ensures that their products not only meet the current demands of high-tech industries but also anticipate future needs.

A Global Vision for a Precision-Driven Future

With a global perspective and a commitment to excellence, SSDC continues to expand its reach and influence in the superabrasives market. Their investment in state-of-the-art technology and infrastructure, coupled with their unwavering commitment to quality and safety, positions them as a leader in the production of grinding stones. As industries evolve and the demand for precision and efficiency grows, SSDC remains at the forefront, ready to meet the challenges of tomorrow.

Conclusion

Grinding stones are foundational to industries' pursuit of precision and innovation. Sea Shore Diamond Industrial Co., Ltd. (SSDC) stands at the forefront, providing superabrasive solutions that fuel progress across sectors. Our unwavering commitment to quality, innovation, and global excellence secures our position as a trusted partner in the dynamic world of manufacturing and industrial processing. For additional details on their offerings or to explore how they can contribute to your goals, feel free to reach out to them. They stand ready to bolster your success and jointly discover innovative solutions.