Maximizing Mold Performance with FENG ZHOU Guide Pins

2024-03-29Mould & Die From:FENG ZHOU

Introduction

In the ever-evolving landscape of mold manufacturing, precision and durability stand as the pillars of excellence. FENG ZHOU, a leader in the industry, recognizes the critical role guide pins play in achieving these standards. This deep dive into guide pins by FENG ZHOU explores their significance, applications, manufacturing intricacies, and the nuanced process of selection. Our commitment to advancing mold performance through innovation and meticulous engineering sets the stage for a discussion on how guide pins are redefining the boundaries of precision and durability in mold design.

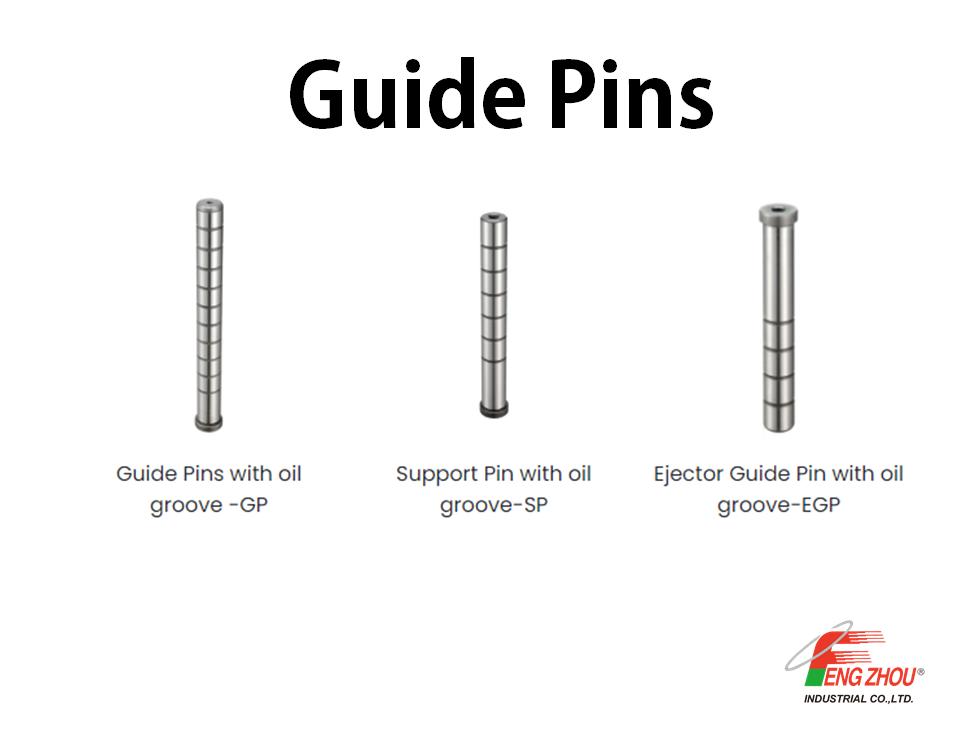

What Are Guide Pins?

Guide pins stand as the cornerstone of mold accuracy, facilitating flawless alignment between mold halves. These components are not just hardware; they are the embodiment of precision, ensuring every product meets stringent quality standards.

Guide Pins Uses and Applications

Guide pins are indispensable across multiple sectors, each with unique requirements that highlight the adaptability and precision of these components:

- Automotive Industry: In automotive manufacturing, guide pins ensure the precise alignment of molds for components like engine parts and dashboard panels, crucial for maintaining high safety and performance standards in vehicle production.

- Electronics: Essential for the electronics industry, guide pins facilitate the assembly of complex circuit boards and components. Their role is critical in ensuring the accurate placement of parts, which is vital for the functionality and reliability of consumer electronics, including smartphones and laptops.

- Medical Devices: The medical device sector relies on guide pins for the accurate production of instruments and implants. These components are key to manufacturing products that comply with rigorous health and safety regulations, ensuring that patient care is supported by reliable and precise medical equipment.

These applications demonstrate the wide-ranging impact of guide pins on modern manufacturing, underscoring their importance in producing detailed, defect-free components across industries.

Guide Pins Manufacturing Process

FENG ZHOU's manufacturing process for guide pins is a testament to our dedication to quality. Through sophisticated engineering techniques, including precision turning and milling, we ensure each pin meets exacting standards. Our commitment extends to selecting superior materials that promise durability under the rigors of mold operation, ensuring our guide pins stand the test of time.

Selecting the Right Guide Pins

The journey to selecting the perfect guide pin is nuanced, reflecting the mold's specific demands. FENG ZHOU's expertise shines here, guiding clients through choices that consider the mold's size, complexity, and the nature of the materials being processed. Our tailored approach ensures each mold is equipped with guide pins that optimize performance and extend mold life.

Conclusion

In the realm of mold design and manufacturing, FENG ZHOU stands as a beacon of excellence, driven by an unwavering commitment to precision and durability. Our guide pins are more than components; they are your assurance of flawless production. By partnering with FENG ZHOU, you're not just choosing guide pins; you're embracing a legacy of quality and innovation designed to propel your operations to new heights.

For more information on our products and how we can support your manufacturing needs, please contact us or explore our website.