How to Choose Wire for Wire EDM Machine?

2021-12-14Machinery

What is a wire EDM Machine?

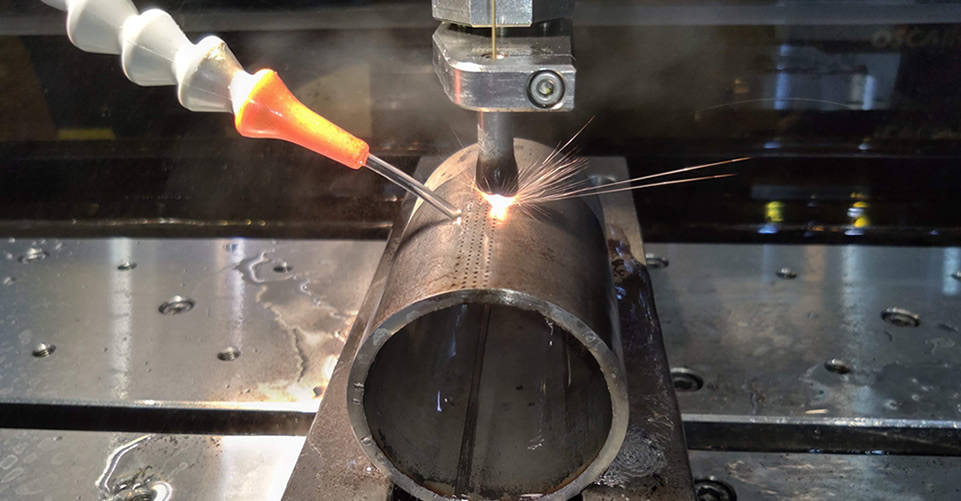

Wire EDM machines produce complicated structures using a tiny, moving wire electrode, always via voids (the wire must pass completely through the workpiece). Machines may automatically cut and rethread the wire, allowing for much longer unattended machining times. All modern machines are entirely immersed in a filtered water dielectric fluid, and dirt is removed from the spark gap area using high-pressure flushing.

The Wire EDM manufacturers have compared its method to cutting metal, wood, or plastic using a band saw. A long, thin brass alloy or copper wire wound on spools substitutes the saw blade to remove material. The resemblance to traditional machining ends there because the wire in EDM processing never touches the workpiece.

Sinker EDM machines of the CMAX S1470 type are advanced CNC machines produced by EDM manufacturers. It comes with motion machining in 3D mode. The machine's body is built of cast iron and can support loads of up to 6000 kg. THE OPTIONAL ELECTRODE HEADS OF the C, A, and B axes may control the six axes.

How to Choose Wire for Wire EDM Machine?

It used to be simple to choose EDM wire since there were only two options: copper or brass. There are now more electrode options for wire EDM than sinkers. Below are some things to consider while choosing wire from EDM manufacturers,

1.Conductivity:

This is a measurement of a material's capacity to conduct electricity. The greater the wire's conductivity, the more power can be given to the workpiece in EDM. Increased cutting speeds are common because better conductivity is more efficient.

2.Tensile strength:

Tensile strength refers to a material's greatest load-bearing capacity based on its resistance to stretching and breaking. It is calculated by dividing the maximum load in pounds per square inch by the wire's cross-sectional area.

High-tensile EDM wire has superior edge straightness, making it an excellent choice for single-pass components and wires with small or fine diameters to reduce wire breakage. Another use that necessitates strong straightness and resistance to wire breakage is wire cutting tall pieces.

3.Vaporization temperature:

Flushability is best achieved when the wire's melting/vaporization temperature is low. Instead of polluting the gap with resolidified "chips," we want the wire surface to evaporate, turning fast into gases.

Melting will occur while utilizing longer times (roughing). Even though low-temperature electrode alloys (zinc-coated) create chips, they form bigger craters on the wire surface, which move more water and impurities away from the gap and facilitate cleansing.

As a result, tungsten and moly wires, which have high melt/vaporization temperatures, cut gradually and flush poorly but are adequate for skim cuts where crisp geometry and component straightness are important.

4.Fracture resistance:

Fracture resistance of an EDM wire is best defined as wire toughness or resilience because there is no actual index or "rating" for it. It refers to the capacity of the wire to withstand the impacts of the spark gap's very dynamic environment.

5.Hardness:

Tensile strength is frequently confused with hardness. A wire's flexibility, or capacity to elongate, is determined by its hardness or temper. EDM wires are classified as soft or hard in this category. Firm wire threads better than a softer wire on closed-guide machines, while a soft wire taper cuts better. A firm wire will also give the most reliable auto-threading.