Differences Between Plastic Injection Molding and Plastic Insert Molding

2024-07-03Mould & Die

In modern manufacturing, plastic molding techniques are widely used for producing various products. Two common and important plastic molding techniques are plastic injection molding and plastic insert molding. Although both techniques are widely applied, they have distinct differences in terms of process and application scenarios. This article will introduce these two techniques in detail and analyze the differences between them.

Plastic Injection Molding

Plastic injection molding is a process where molten plastic material is injected into a mold, cooled, and solidified to form a specific shape. This technique is suitable for high-volume production, capable of efficiently and accurately manufacturing complex plastic parts.

Features:

- High Efficiency Production: Capable of rapidly producing large quantities of identical parts, suitable for large-scale production.

- Design Flexibility: Can manufacture products with various complex shapes and fine details.

- Material Variety: Can use various plastic materials, such as PP, ABS, PE, etc., chosen based on product requirements.

Applications:

- Consumer electronics housings

- Automotive interior components

- Household appliance parts

- Industrial components

Plastic Insert Molding

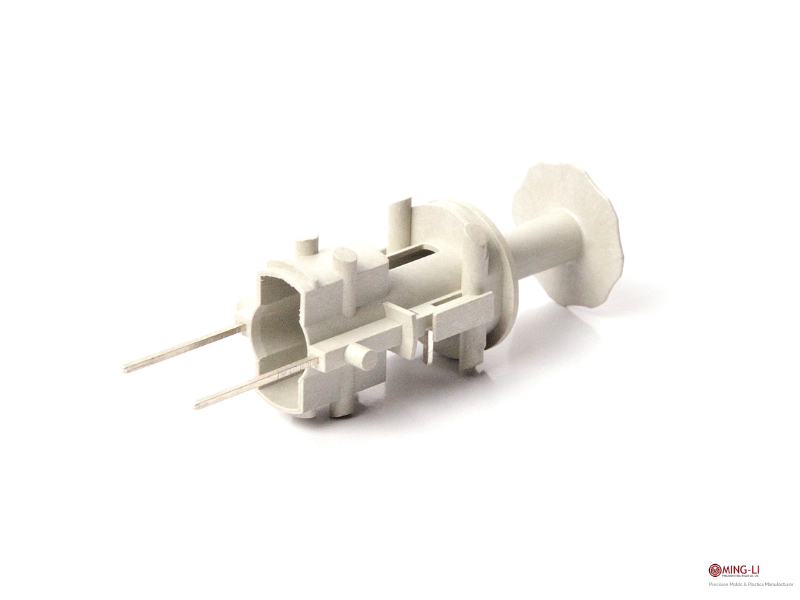

Plastic insert molding is a process where pre-formed components, such as metal or other material inserts, are placed into a mold, and molten plastic is injected to form a single, integrated part. This technique is often used for products that require the combination of multiple material properties.

Features:

- Enhanced Structural Integrity: Combining metal inserts with plastic improves the mechanical strength and durability of the product.

- Reduced Assembly Steps: Combines the installation of inserts with the molding process, reducing subsequent assembly steps and increasing production efficiency.

- Design Versatility: Allows for the integration of multiple materials and functions, meeting complex design requirements.

Applications:

- Automotive parts, such as sensor housings and connectors

- Electronic product connectors

- Medical devices, such as surgical instruments and diagnostic equipment

- Industrial machinery components

Main Differences between Plastic Injection Molding and Plastic Insert Molding

Process Flow:

- Plastic Injection Molding: Involves injecting a single material into the mold to form a part, primarily used for pure plastic components.

- Plastic Insert Molding: Involves placing inserts into the mold before injecting plastic, creating a product that combines multiple material properties.

Application Scenarios:

- Plastic Injection Molding: Suitable for scenarios requiring the efficient production of large quantities of identical plastic parts.

- Plastic Insert Molding: Suitable for scenarios requiring the combination of metal and plastic to enhance product strength and functionality.

Product Characteristics:

- Plastic Injection Molding: Produces parts mainly composed of a single plastic material, emphasizing production speed and cost efficiency.

- Plastic Insert Molding: Produces parts that combine the advantages of inserts and plastic, emphasizing structural strength and functional diversity.

Application in Bicycle Parts Manufacturing

At Ming-Li, we specialize in both plastic injection molding and plastic insert molding for producing high-quality bicycle components. Whether you need purely plastic parts or components that integrate metal inserts for enhanced performance, we have the expertise and capabilities to meet your needs.

For instance, in the production of bicycle components, plastic injection molding can be used to manufacture parts such as:

- Handlebar Grips: Lightweight and durable, providing comfort and control.

- Chain Guards: Protecting the chain and rider, designed for precision and strength.

Plastic insert molding, on the other hand, is ideal for parts that require added strength and functionality, such as:

- Pedal Bodies: Combining metal inserts with plastic for increased durability and performance.

- Brake Levers: Integrating metal inserts for enhanced mechanical strength and reliability.

Ming-Li’s extensive experience and advanced manufacturing capabilities ensure that we can produce high-quality bicycle components using both plastic injection molding and plastic insert molding techniques. For more information on our bicycle parts manufacturing process, please visit our bicycle components page.

In summary, plastic injection molding and plastic insert molding each have their advantages and suitable applications. By understanding the specific needs and design requirements of your products, choosing the appropriate molding technique can significantly enhance product quality and production efficiency.