What is Guide Bushings in Precision Molding?

2024-05-30Mould & Die

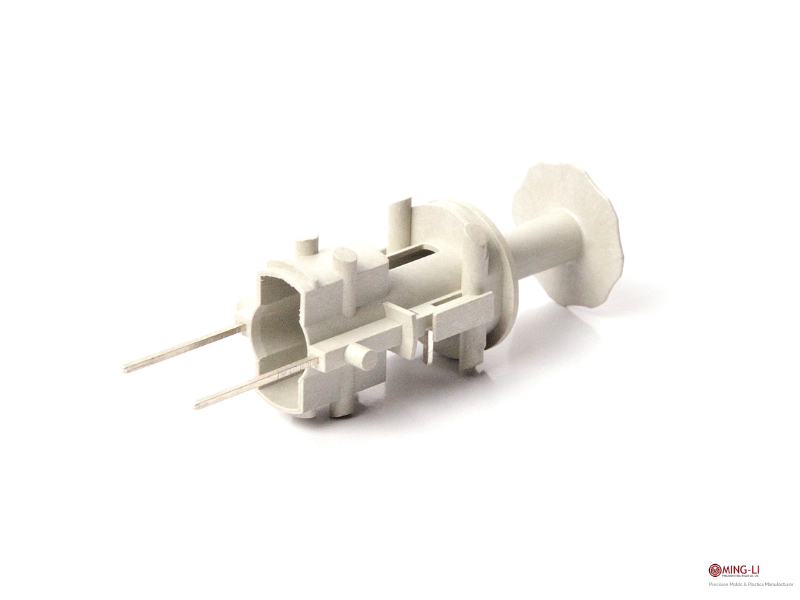

Guide bushings are integral components in the precision molding industry, often overlooked but essential for the seamless operation of molds. In this article, we explore the critical role that guide bushings play, focusing on their application in maintaining the alignment and efficiency of the injection molding process.

Functionality and Importance

Guide bushings ensure the precise alignment and smooth operation of guide pins within a mold. By reducing friction and wear, they extend the life of both the mold and the guide pins, which is crucial for maintaining production quality and efficiency.

Material and Design Considerations

The choice of material for guide bushings is critical. High-quality, wear-resistant materials like bronze or steel are commonly used to withstand the harsh conditions of molding operations. The design of these bushings also plays a significant role, as they must be tailored to fit specific mold configurations and operational requirements.

Applications in Various Industries

While commonly used in automotive and consumer electronics manufacturing, guide bushings are also vital in other sectors such as medical device production and aerospace. Their ability to provide stability and precision makes them indispensable across these diverse industries.

Choosing the Right Guide Bushings

Selecting the appropriate guide bushings involves understanding the specific needs of your molding process, including the type of material being molded and the expected production volumes.

Choosing the right guide bushing involves several key considerations:

- Material Compatibility: Select materials that can withstand the wear and pressures of your specific molding process. Common materials include hardened steel for durability and bronze for reduced friction.

- Operational Requirements: Consider the type of molding operation and the environment. High-temperature processes might require different materials compared to standard applications.

- Mold Design: Ensure the bushing fits precisely within your mold design. Proper fit is crucial to prevent misalignment and wear.

- Load and Speed: Evaluate the operational load and speed of the mold components. The bushing should be capable of handling the expected operational stress without failure.

- Expert Consultation: Consulting with manufacturers and experts like those at Fengzhou Precision Mold Limited can provide insights into the best choices based on extensive industry experience and technological expertise.

Conclusion

Guide bushings may be small components, but their impact on the molding process is significant. Ensuring the use of high-quality bushings is essential for any operation that values precision, efficiency, and longevity in its production processes. At Fengzhou Precision Mold Limited, we understand the critical role these components play in enhancing the quality and efficiency of manufacturing processes. We invite you to contact us to explore how our expertise can benefit your specific needs.

For more information and assistance with guide bushings, please visit Fengzhou Precision Mold Limited or contact our team directly. Together, let's achieve excellence in precision molding.