What is Carbon Brush? What Are the Advantages of the Carbon Brushes?

2021-12-14Auto Parts

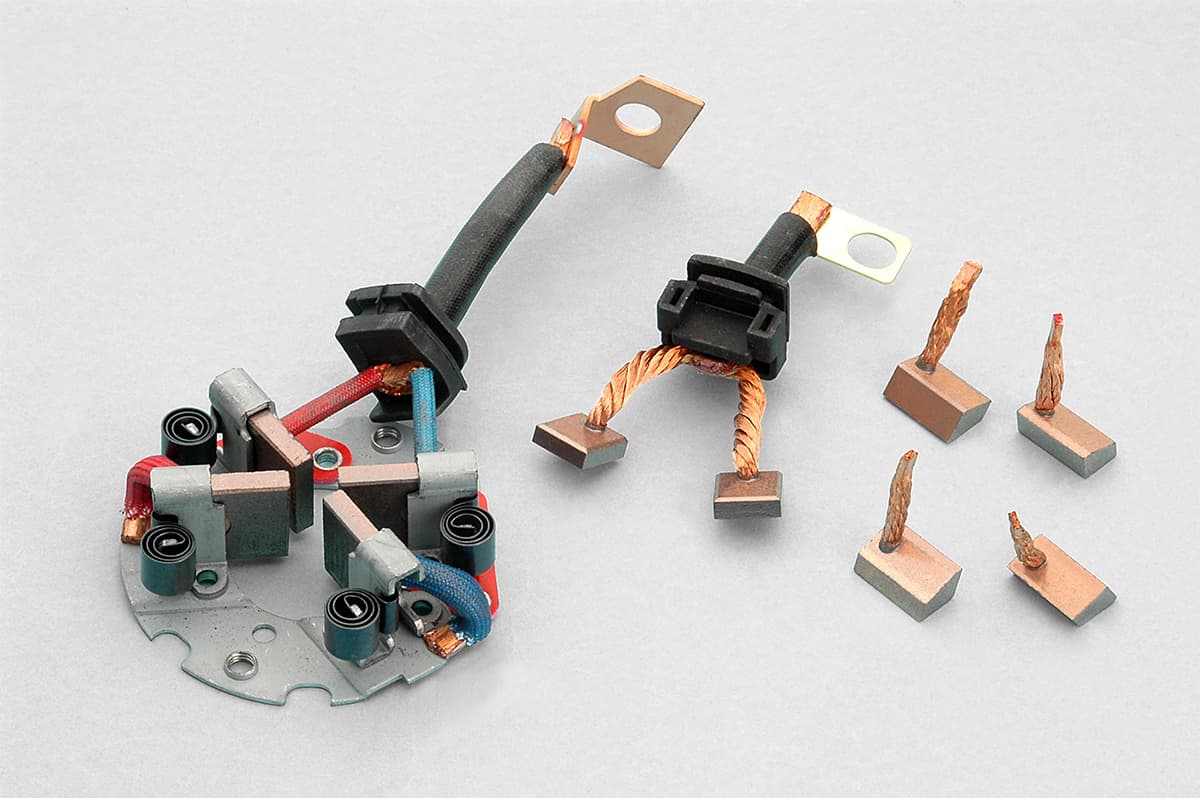

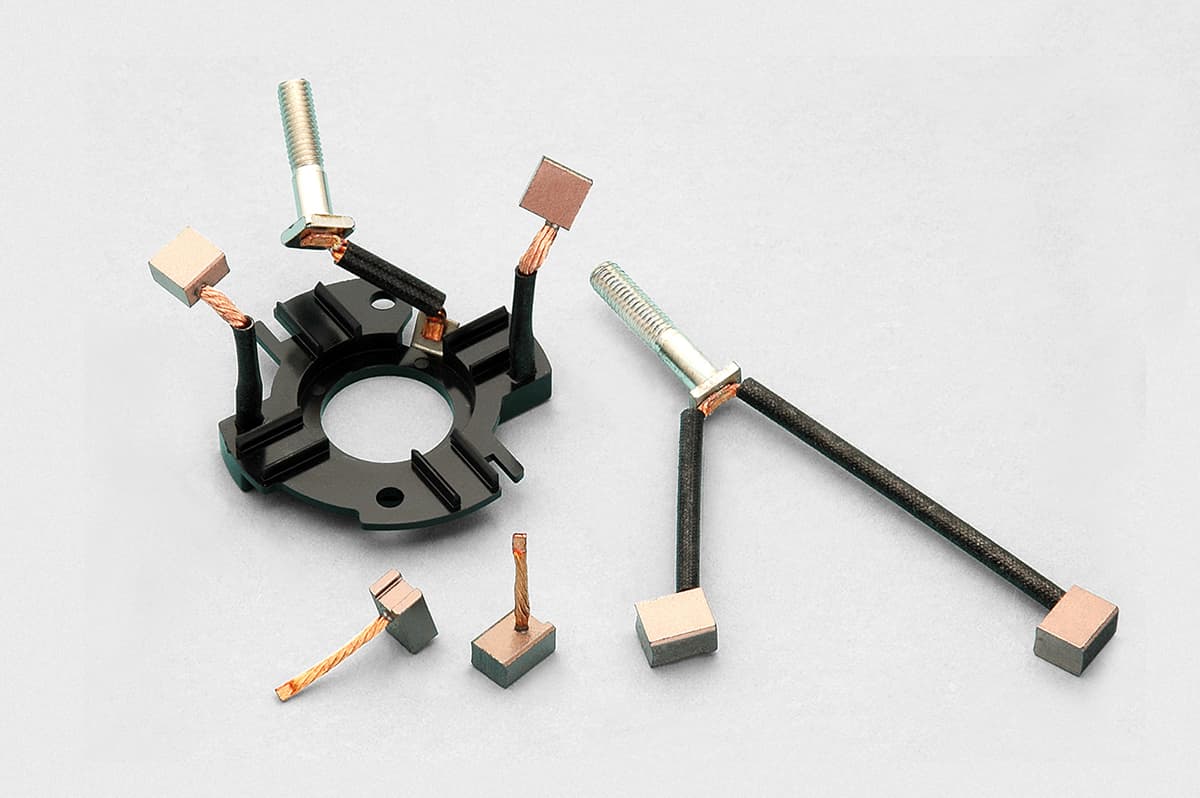

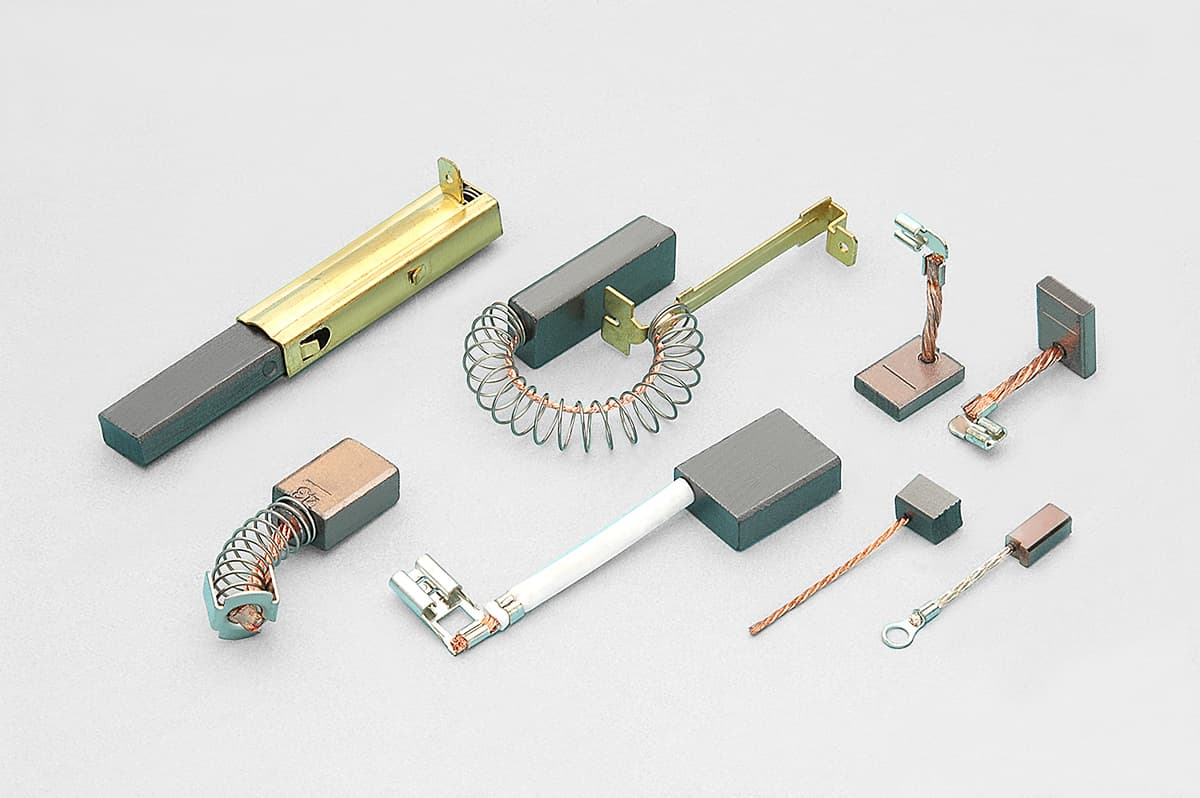

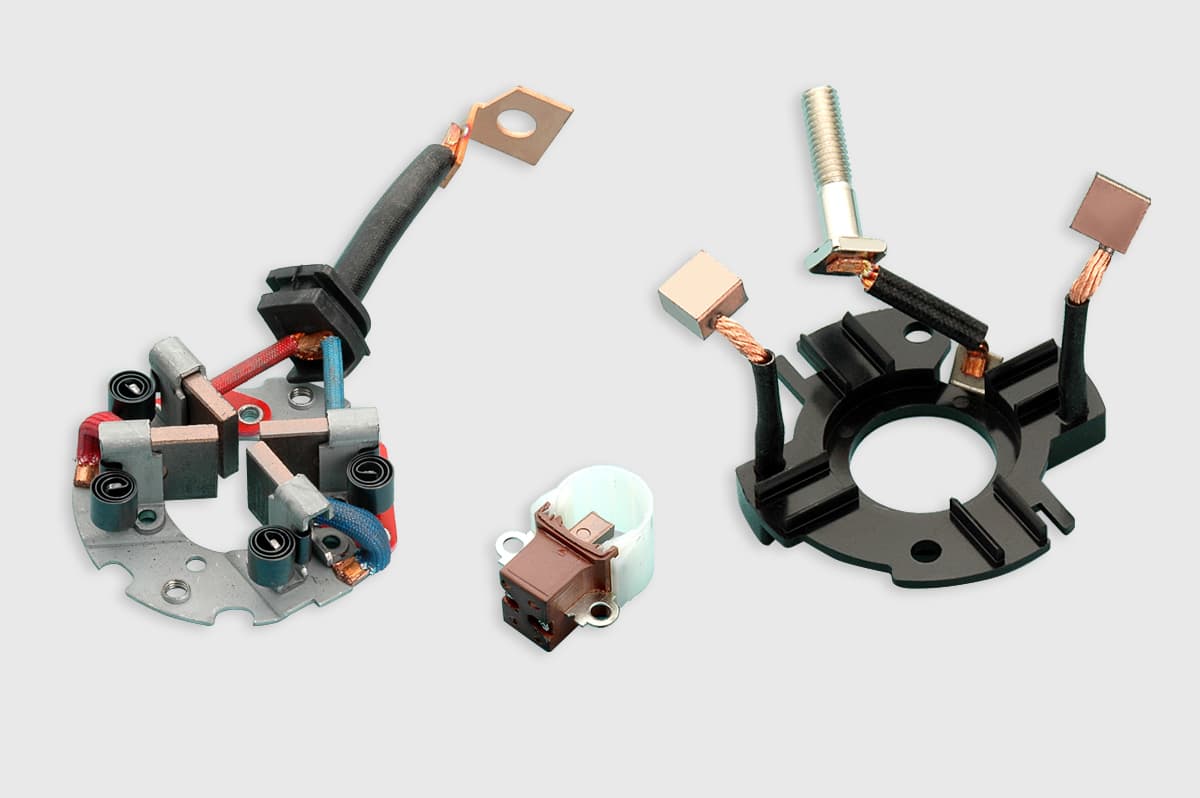

Additionally referred to as a motor brush or a carbon brush, it is a very tiny component of an electric motor responsible for transporting electrical current between the motor's stationary and spinning wires.

What Are They Made Of?

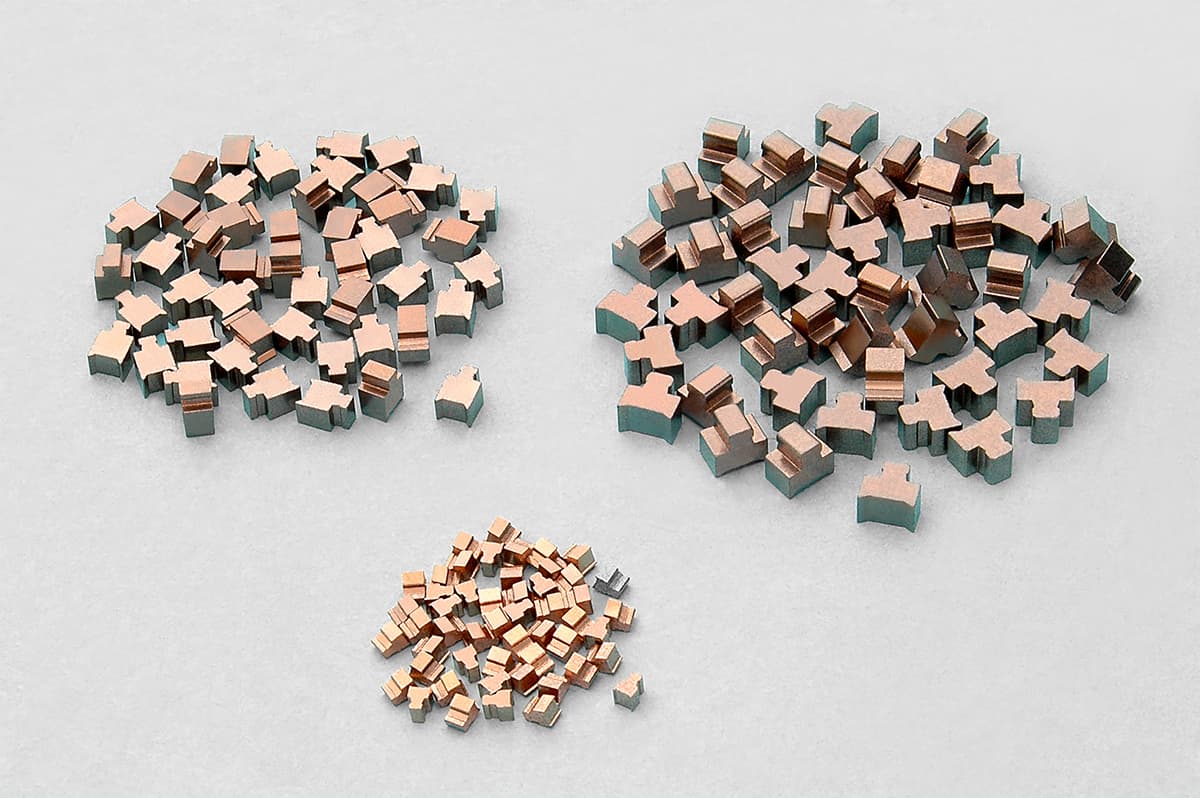

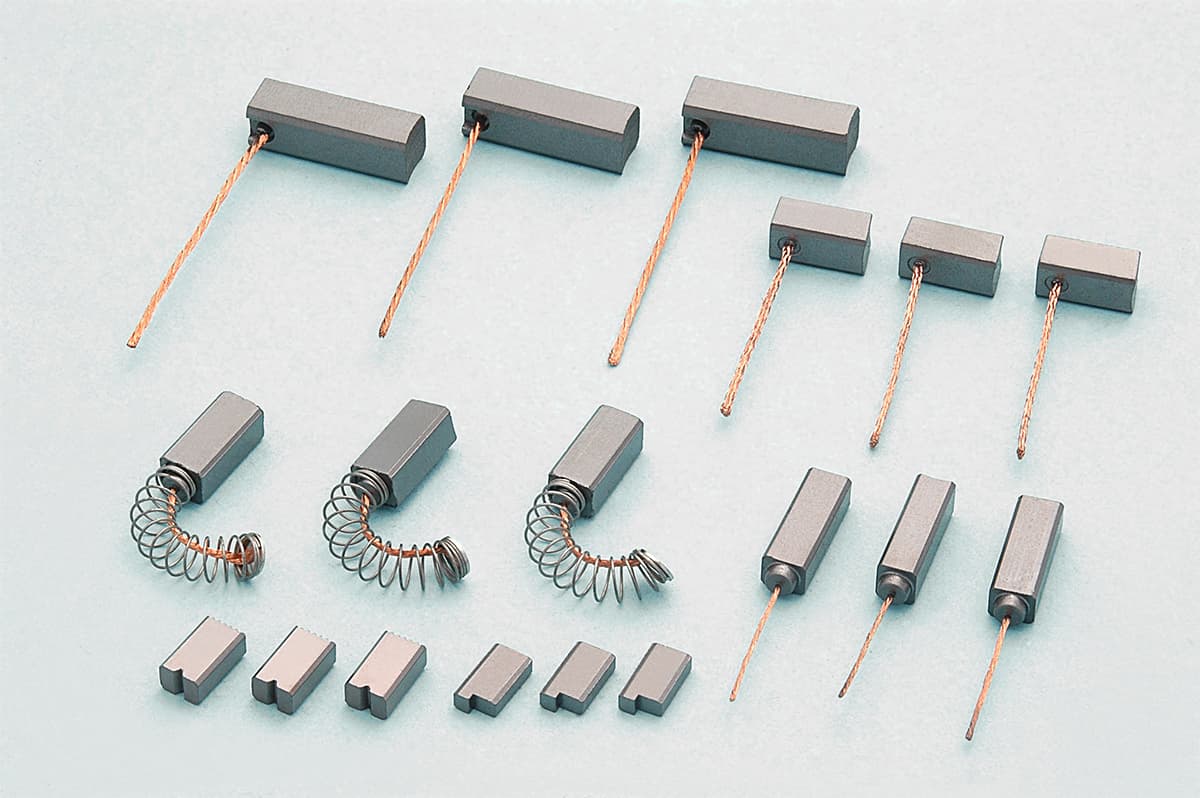

A carbon brush or motor brush is often constructed from various kinds of carbon materials (such as natural and bonded carbon), each of which is connected to a variety of different terminals (also known as terminals). Carbon is an excellent conductor of electricity because it is both soft and conducts efficiently. Carbon brushes deteriorate over time due to their supple nature and must be changed often.

Advantages of a Carbon Brush:

Some of the top advantages are explained below

They Have High Melting Point

Carbon metal has a melting point that is often greater than that of copper and other common metals. Carbon brushes have a melting temperature of 3550 degrees Celsius, while copper has a melting point of just 1080 degrees Celsius.

Motor Brushes/Electrical brush on a dc motor are well-known due to their proximity to the commutator. As a result, while the motor is operating, it produces sparks and friction between the brushes and the commutator. When the temperature rises, the copper brush becomes unstable, which is why we use it in the first place.

Usage of Soft Metal

In contrast to the copper brush, the carbon brush/electrical brush is often made of a softer metal. While the motor is operating, the brush and commutator are always in contact, resulting in friction. Due to the brush's softness, the commutator will remain undamaged. Because copper is so hard, we will damage the commutator if we use a copper brush.

Negative Temperature Coefficient

This is not a good idea owing to the negative temperature coefficient of the carbon brush or motor brush. Because there is a direct connection between rising temperature and lowering resistance, the temperature of the motor increases during operation as a consequence of friction and heat production. This is common knowledge. As a result of the increased temperature, the resistance of the carbon brush will drop, amplifying the current surge.

Amorphous

Despite its rectangular form, the carbon brush is surprisingly malleable, which makes it an indispensable tool. To get a circular commutator, we just need to connect our new brush (electrical brush) to it and power on the motor.

Easy Lubrication

It, like the Evolution Brushes and the carbon brush, is self-lubricating. As a consequence, there is no need for additional cooling oil, lubricating oil, or Greece. When the engine is turned off, the carbon brushes are automatically permitted to cool.

Some Down points you need to know:

High contact resistance results in a voltage loss of about 2 V. Consequently, they are not well-suited for usage in tiny devices where voltage represents a significant part of the overall power of the device."

In order to effectively dissipate heat without significantly raising the working temperature, the commutator must be bigger than it would be with copper brushes due to the high loss.

Compared to copper brushes, which have a higher current density per square centimeter, these brushes need larger brush holders.

Final Remarks:

Despite their critical role in motors and generators, carbon brushes are often neglected. They are what they are because of their carbon and steel components.