Discover the Benefits of Micro Injection Molding for Your Manufacturing Needs

2023-10-20Mould & Die

As technology continues to advance, new and innovative manufacturing techniques have been developed to meet the growing demands of the market. Micro injection molding is one of these techniques that have revolutionized the manufacturing industry, offering endless benefits to companies looking to manufacture smaller components. In this article, we will delve into the benefits of micro injection molding and how it can help your manufacturing needs.

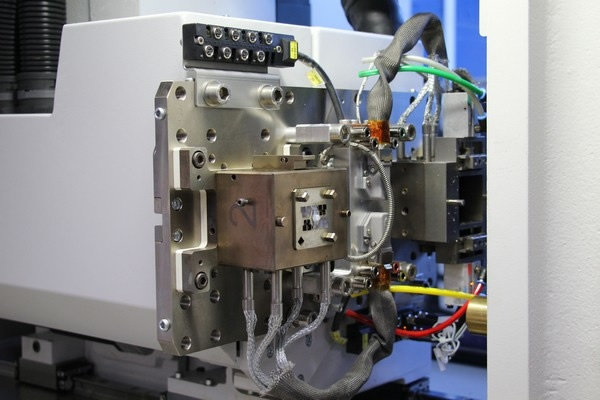

Micro injection molding is a manufacturing process used to produce parts in small sizes and with high precision. The process involves melting plastic pellets and injecting the molten material into a mold cavity. The molten plastic is then left to cool and solidify to create the desired product. Micro injection molding has become popular in recent years due to its ability to produce small, intricate parts with high precision and consistency.

The main advantage of micro injection molding is its ability to create complex geometries with small dimensions. Micro parts generally range from a few millimeters to a few centimeters in size, making it suitable for manufacturing small electronic components, medical devices, and automotive sensors. Micro injection molding allows for the production of parts with tolerances as low as ±0.01mm. This level of precision is not achievable with other conventional manufacturing techniques.

Another benefit of micro injection molding is its ability to manipulate a wide range of materials. Different types of plastic material can be used to manufacture micro parts, including thermoplastics, thermosets, and elastomers. These materials have varying physical and chemical properties, making them suitable for different applications. For example, polycarbonate is a transparent material that is ideal for manufacturing optical components, while Nylon is highly durable and suitable for automotive applications.

Micro injection molding is also cost-effective compared to other manufacturing techniques. The process allows for mass production of parts with high-speed injection molding machines that can produce up to 1000 parts per hour. This means that companies can produce large quantities of parts in a shorter time, reducing production costs. Additionally, micro injection molding has a low scrap rate, making it an efficient manufacturing technique.

Moreover, micro injection molding is environmentally friendly. The process requires less material to create small parts, reducing waste and energy consumption. The production of small parts also means that less packaging materials are required, reducing the carbon footprint of the manufacturing process. Micro injection molding is an ideal technique for companies looking to incorporate sustainable manufacturing practices in their operations.

In the medical industry, micro injection molding has been especially useful for the production of medical devices. The process allows for the production of small, intricate parts that are needed for medical devices such as catheters, syringes, and hearing aids. These medical devices require precise and reliable manufacturing processes to ensure patient safety. Micro injection molding offers the precision and consistency required to meet these standards.

Micro injection molding is also useful in the aerospace and automotive industries. These industries require small, complex parts that can withstand harsh conditions. Micro injection molding can produce parts that are highly durable and resistant to chemicals and extreme temperatures. Additionally, micro injection molding is a highly customizable technique that allows manufacturers to produce parts that meet specific requirements and standards.

In conclusion, micro injection molding is a cost-effective, environmentally friendly, and precise manufacturing technique that has revolutionized the production of small parts. It offers a range of benefits to companies looking to produce high-quality components, from medical devices to automotive sensors. With its ability to create complex geometries with small dimensions, manipulate a wide range of materials, and achieve high precision, micro injection molding is a technique that should be considered for any manufacturing needs.