Innovating Motion: The Role of U-Joints in Hybrid and Electric Vehicles

2024-05-02Auto Parts

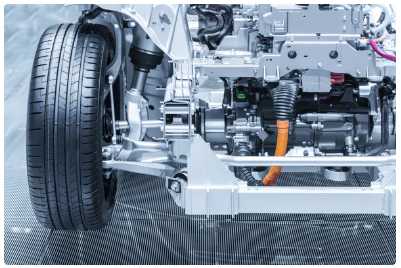

As the automotive industry pivots towards sustainability, the transition from gasoline-powered vehicles to hybrid and electric vehicles (HEVs and EVs) has accelerated. This shift is not just about changing fuel sources; it's about reimagining vehicle dynamics and componentry, including the essential universal joint (U-joint). The transition from gasoline-powered vehicles to hybrid and electric vehicles (HEVs and EVs) marks a significant shift in the automotive industry, bringing with it a new era of drivetrain technology. This shift isn't merely about replacing the combustion engine with an electric motor; it involves rethinking the entire vehicle's mechanical system, including components like universal joints (U-Joints). In gasoline vehicles, U-joints have been fundamental in transmitting power from the engine to the wheels, allowing for a smooth transfer of torque despite the angles and misalignments within the drivetrain. As we move to HEVs and EVs, the role of U-joints becomes even more critical. Electric motors deliver power differently from traditional engines, offering instant torque from zero RPM. This instant power delivery demands U-joints that can handle sudden and high torque levels while operating efficiently over a wide range of speeds. Moreover, the quiet nature of electric vehicles puts a spotlight on NVH (Noise, Vibration, and Harshness) characteristics, necessitating U-joints that can operate silently to maintain the vehicle's quiet profile. The engineering behind U-joints for electric and hybrid vehicles also accounts for the reduced space and weight requirements. As vehicle designs become more compact, every component must be optimized for space and weight while maintaining or enhancing performance. This has led to innovations in U-joint design, including the use of lighter materials and more compact configurations that can withstand the unique demands of electric powertrains. HYB Universal Joint, with its deep industry expertise, has been at the forefront of adapting U-joints for this new era. Design considerations now include the ability to withstand higher torque levels, minimize noise, vibration, and harshness (NVH), and manage the faster rotational speeds typical of electric drivetrains. Our commitment to innovation is evident in our approach to customization and flexibility. HYB Universal Joint excels in creating bespoke solutions for HEVs and EVs, addressing unique requirements with precision-engineered U-joints that enhance vehicle efficiency and drivability. Our portfolio includes collaborations with leading automotive manufacturers, developing U-joints that seamlessly integrate into advanced HEV and EV systems. These case studies highlight our ability to meet complex challenges, from optimizing material selection to refining design for enhanced durability and performance. Looking Ahead: U-Joints and the Future of Mobility As the automotive landscape continues to evolve towards a more sustainable and technologically advanced future, HYB Universal Joint stands at the forefront of this transformation. Our dedication to innovation, coupled with a deep understanding of the nuanced requirements of hybrid and electric vehicle drivetrains, positions us as a key player in shaping the future of mobility. By continuously refining our U-joints to meet the ever-changing demands of the industry, we commit to driving forward with solutions that enhance efficiency, performance, and sustainability. HYB Universal Joint is not just a part of the automotive evolution; we are actively crafting the road ahead, ensuring a smoother journey towards a greener, more efficient world.U-Joints: From Gasoline to Electric

Tailoring U-Joints for the Future

Custom Solutions for Emerging Needs

Demonstrated Excellence

As HEVs and EVs continue to evolve, so too will the technologies that support them. HYB Universal Joint remains dedicated to advancing U-joint technology, anticipating future trends, and meeting the needs of tomorrow's vehicles.Conclusion