What are the Functions of Carbon Brush?

2021-11-18Auto Parts

What are the Functions of Carbon Brush?

A carbon brush is a type of electromechanical component that conducts electric currents in motors, generators, or alternators from rotating parts to static parts that require power. Carbon brushes are also known as sliding contacts that transmit electrical energy to the rotating motors from the stationary wires.

Below are the primary functions of carbon brushes:

Automotive Uses

Many automotive machines such as cars run on DC or direct current motors. The carbon brushes used in such machines help in transmission of current from the converted mechanical energy to the electric power in the alternators in AC or alternating current form. Alternators require current for producing a magnetic field.

A carbon brush meant for automotive uses transmits the electric current that the alternator needs to function. These brushes are very common in vehicles that run on diesel or those that need oil to operate. These are also necessary for airbags to work during impact as well as for steering wheel while the vehicle is in motion.

Domestic Use

Home equipment running on rotating components that require power needs carbon brushes as well for demands of power transmission. Good examples of home machines that need carbon brushes including gardening tools, office printers, and other types of power tools.

Carbon brushes can be used for many of the ordinary appliances you have in your home. The carbon brushes on domestic machines are much smaller compared to the ones used in the industrial machines since they require lesser power. Laundry machines, vacuum cleaners, and dishwashing machines are also daily household items that make use of carbon brushes.

The smaller items such as children’s play toys also use micro-carbon brushes helping power batteries for the small motors.

Industrial Use

The carbon brushes are used on the rotary commutator electric switches in many heavy-duty equipment such as electric motors and electrical generators. The commutator switches can help in occasional reversal of the current flow’s direction between external circuits and rotors, primarily DC or direct current machines such as DC generators, DC motors, and universal motors.

A carbon brush supports AC or alternating current motors and DC or direct current motors alike. Carbon brushes can also support the processing equipment motors such as in windmills, hydropower generation plants, and cement plants. Thanks to their widespread use in the construction trucks that have engines, the carbon brushes can support locomotive industry as well and even help start vehicles that run on batteries.

With the carbon brushes taking in all the wear and tear, static parts and rotating parts have protection. The industrial carbon brushes feature a unique design for containing the high heat generator from the moving parts in different heavy industrial equipment.

Different Types of Carbon Brushes

The carbon brushes can make the electric motors work through current transmission. Back in the days, wires were used as carbons. However, due to their quick wear and tear, today’s industrial standards design them to squares to boost the efficiency and functionality of commutators in the electric motors. The most common types of carbon brushes include:

- Carbon brushes

- Electrographite carbon brushes

- Graphite carbon brushes

- Metal graphite carbon brushes

Product List -

Carbon Brush for Automobile

Carbon Brush for Motorcycle

Carbon Brush for Micromotor

Carbon Brush for Home Appliance

Electiric Contacts & Others

Motor Carbon Brush for Health Equipment

Carbon Brush for Power Tool

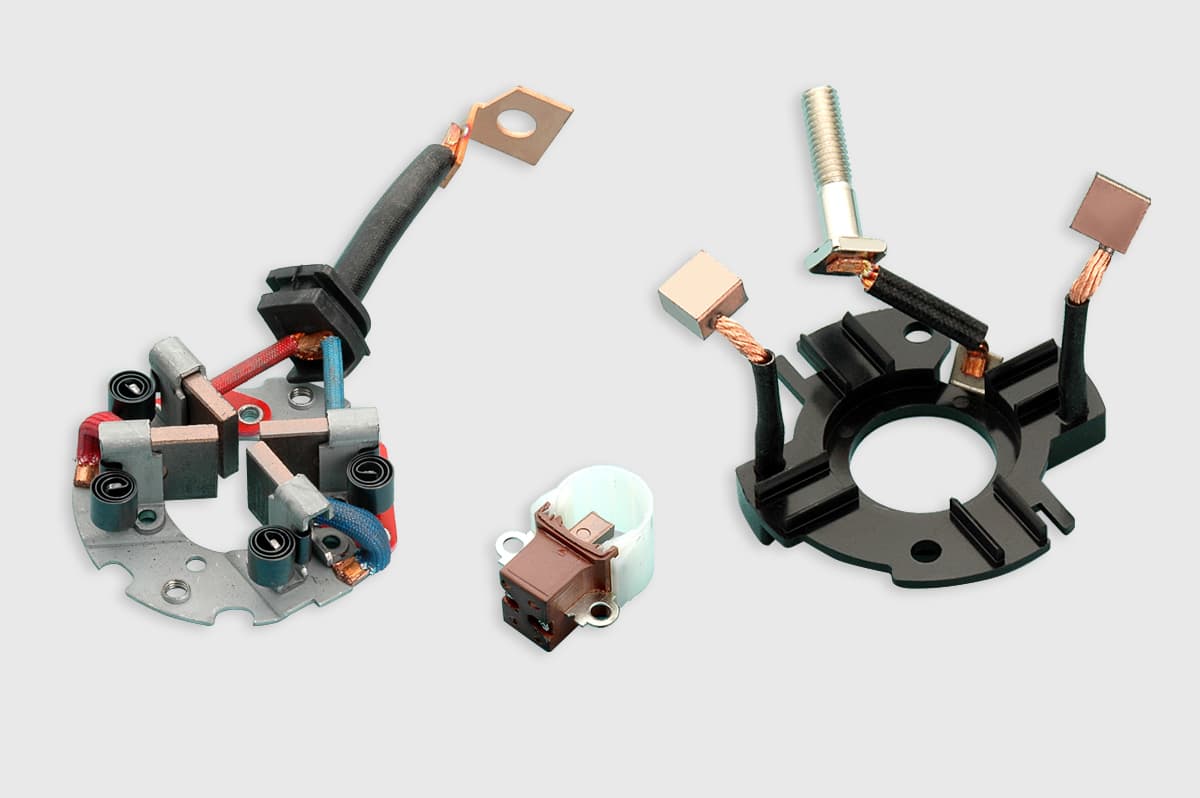

Holder Assembly