Types of Electrical Discharge Machining (EDM Machine)

2021-11-18Machinery

Types of Electrical Discharge Machining (EDM Machine)

Most of the durable items you see around you boast of complex configurations and intricate designs made through the metalworking process. Just so you know, there are three integral parts in metalworking, and these are forming, joining, and finally cutting.

During the fabrication of metals, such as precision machining, there are various methods used for forming, cutting, and joining metals. Although many traditional methods provided excellent results, it was a great relief that EDM or electrical discharge machining was discovered.

It is because EDM machines are reliable, efficient, and make it possible to achieve the most extreme accuracies. In addition, these machines can also come in handy in complex metalworking areas and cutting-edge machining applications where traditional methods are difficult.

What are EDM Machines?

EDM or electrical discharge machining is a form of non-traditional electric-controlled that uses thermal energy for removing metal from a certain workpiece. An EDM machine uses thermal erosion for removing small conductive metal pieces through leveraging electrical discharge between the dielectric fluid, the cutting tool, and the piece that is being worked on.

During the process of EDM, there is a high frequency electrical discharge that is released within the gap between the piece that is being worked on and the cutting tool or electrode. The heat will vaporize the small metal bits where the electrical charge is being focused on, with the stream of dielectric fluid washing it away. Temperatures can reach up to 15,000 degrees Fahrenheit during the process.

The following are the most common types of EDM machines you can find in the market today:

Hole Popper or Drill EDM

It is a type of EDM machine that is used for making small holes in metal pieces. This machine uses a conductive tube as the electrode as well as seamless flow of the dialect fluid around and through this electrode for flushing out the vaporized metals. The ability of the machine to drill precise and accurate holes even on exotic and hard materials continues to be among the modern development fabrication industries.

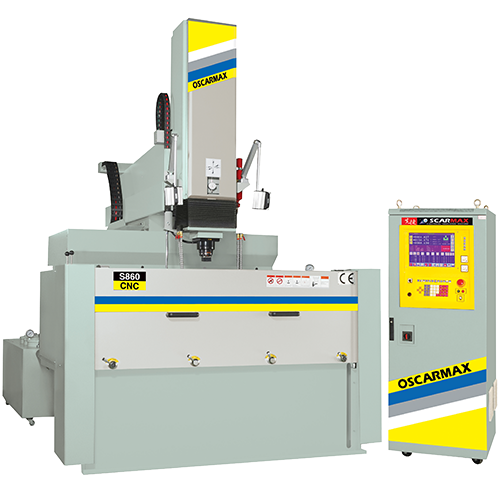

Sinker or RAM EDM

RAM EDM is so far the oldest type of EDM machining that is made up of specifically shaped electrode plunged to the work piece to make sophisticated blind shape activities and cuts. Based from the name of these machines, both the electrodes and work piece in sinker EDM machines are submerged in the dielectric fluid, or viscosity and light weight oils. The right powered generator is used to achieve the desired results.

Cheese Cutter or Wire EDM

Wire or cheese cutter EDM machines use a CNC movement and wire electrode for producing the desired contour or shape. The technique uses the spark erosion for removing the conductive metal, which is the key concept behind the process of EDM.

The wire will travel from the spool through the precision wire guides that the CNC controls in motion. Flushed with deionized water or dielectric for cooling the thin wire and removing the eroded particles, it is safe to say that wire EDM is a very accurate and precise bandsaw.