Tips for choosing EDM Machine

2021-12-14Machinery

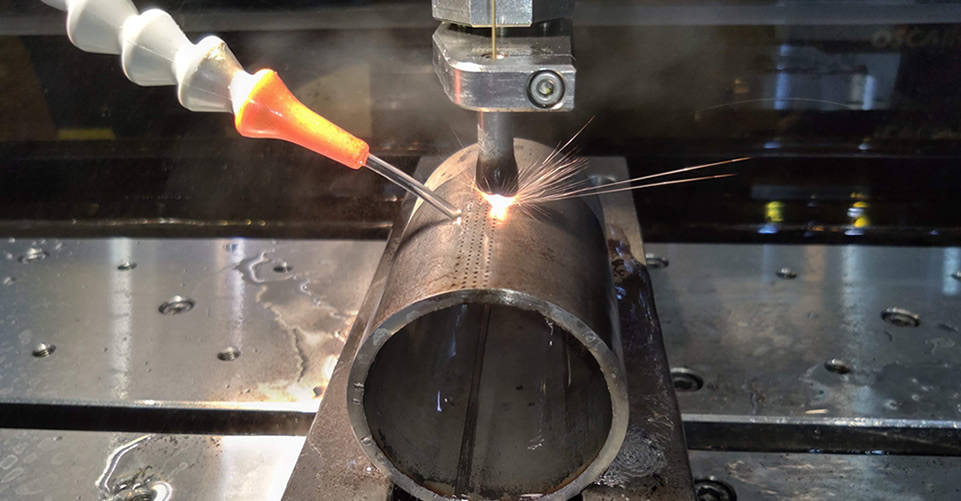

The need for more modern, innovative Electrical Discharge Machine (EDM) drilling technology in hole-making operations have arisen due to the demand for smaller, deeper, and more accurate holes made as quickly and reliably as feasible.

Here are some pointers on choosing an EDM machine that can assist your company in meeting these objectives.

- Look for operational efficiency:

Machine selection is essential when it comes to EDM operating efficiency. Depending on the application, molders can use various equipment, including sinkers, wire, and drilling machines.

When selecting a wire EDM machine, it is important to consider the most recent cost-cutting features. For example, some machines have an operational mode that helps reduce wire consumption by slowing down the wire feed rate.

Choosing the best wire EDM machine is also important for reducing energy consumption and saving money since they offer features that help manage and optimize filtration and pump operation.

- Ease of use and reliability:

Look for an EDM machine that is quick, dependable, and easy to use. It should drill exceedingly tiny holes while maintaining high surface finish quality and accuracy at larger depths. In light of some of today's applications, it's critical to find a system that could drill a 15 mm deep hole which is 0.20 mm in diameter in tough steel while simultaneously drilling a cooling hole of 2.5 mm in diameter 250-mm deep in mold steel, all with minute size and straightness variations from the entrance to exit.

- Ease of maintenance:

Another factor to consider when looking for EDM machines is how easy they are to maintain. It's critical to keep your equipment in good working order. This implies that you must figure out how to repair it if damaged. The sort of locker you pick will determine how easy it is to maintain.

- Types of EDM machines:

When looking for the correct EDM Machine, it's important to understand the different types of EDM on the market. Wire EDM, sinker EDM, and small-hole EDM are the three types of EDM activities to be aware of.

Sinker EDM, for example, makes use of an electrode that has been manufactured into a certain form. After that, the reverse of the shape is imprinted. A servo contour mechanism is used in a sinker EDM to monitor and ensure continuous sparking throughout the operation.

- Supper high-pressure coolants:

Uneven wear increases the probability of a drilling electrode to "wander" off-center, resulting in crooked and slanted holes rather than straight ones. Supper high-pressure coolant/flushing systems assist in averting this scenario by reducing wear and contributing to the production of straighter holes that can be held closer to size from top to bottom.

For example, a 200 mm-deep hole drilled using a digital generator-equipped EDM system with a 1 mm electrode would vary in size from top to bottom, generally less than 0.025 mm.

Conclusion:

These days technically advanced EDM drilling technologies effectively put hole-creating precision in the hands of a machine tool's technological capabilities. Modern EDM drilling devices vastly improve a shop's capacity to reliably create microscopic holes that are more precise and have better surface finishes.